Norlab installation services includes install of all types of laboratories, healthcare and life sciences furniture and equipment – even the ones sold by our competitors.

Product install schedule is designed to maximize uptime and minimize the downtime.

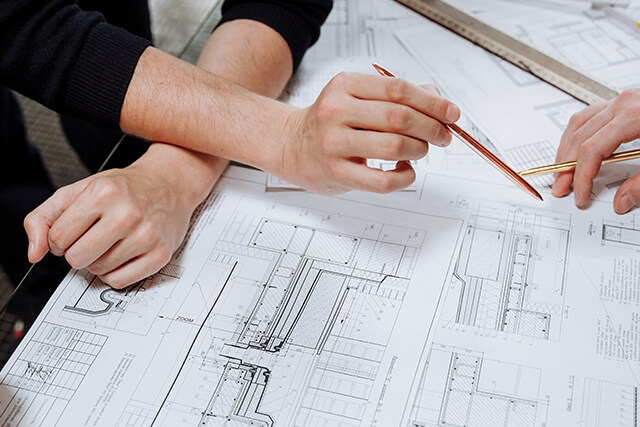

Lab planning and design lays the foundation for efficient scientific work.

There are several types of laboratory environment, and each one can require a completely different approach when planning it. We help clients understand the specific requirements of each project and recommend value added solutions based on their unique goals and needs.

Changes to FF&E during the tender and construction phase of a project can have significant impacts on project cost and schedule. We help builders and architects save time and money by ensuring critical aspects are addressed and identifying and mitigating potential issues that may arise and

We help reduce internal resources requirements while ensuring proper product selection based on best practices and safety requirements. Ultimately improving the quality of work it’s being designed for.

Laboratory Post-Covid design is rapidly evolving, with common issues being identified through multiple studies. One recurring finding is the impact of storage and consumables in the lab space and the challenges they create for proper cleaning and decontamination. As part of the user reviews, we would identify the storage requirements with users and propose storage solutions from Healthcare, Laboratory, and Industrial furniture manufacturers to meet the requirements.

Tyler Holmberg is a highly experienced Senior Product Specialist in laboratory architecture and planning with over 14 years of proven expertise. He possesses extensive skills in various facets of project management, design, and coordination, coupled with remarkable proficiency in drafting and installation of laboratory casework. He has been with Norlab since 2008 and holds a degree in Civil Engineering Technology/Technician from the Northern Alberta Institute of Technology (NAIT).